Meling Biomedical Participated in Vietnam Medi-Pharm Expo 2022 (Hanoi)

Meling Biomedical Participated in Vietnam Medi-Pharm Expo 2022 (Hanoi)

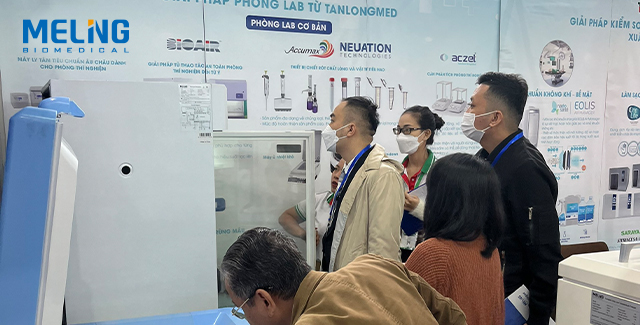

On December 1st 2022 - December 3rd 2022,Meling Biomedical and local distributor jointly participated in Vietnam Medi-Pharm Expo 2022 (Hanoi).

After 27 years of holding, Vietnam Medipharm Expo has proved to be a prestigious professional exhibition with a large number of domestic and foreign companies and enterprises attending. It offers an extensive platform for medical and pharmaceutical enterprises.Meling Biomeidcal worked together with our intimate clients making full use of this opportunity to share and exchanges experience with peer in cryogenics refrigeration industry.

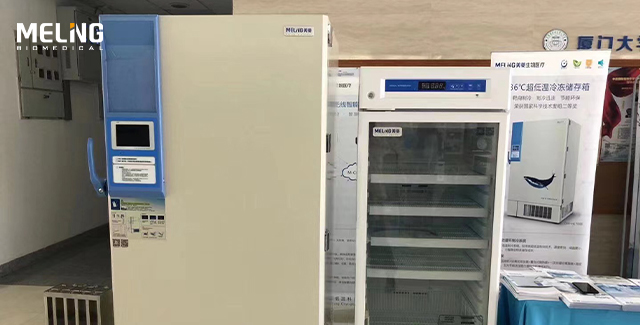

During the exhibition, in A01-A02, Hanoi International Exhibition Center, several series of hot-selling products were exhibited respectively:

Pharmacy Refrigerator: YC-75L, YC-315L, YC-150EW

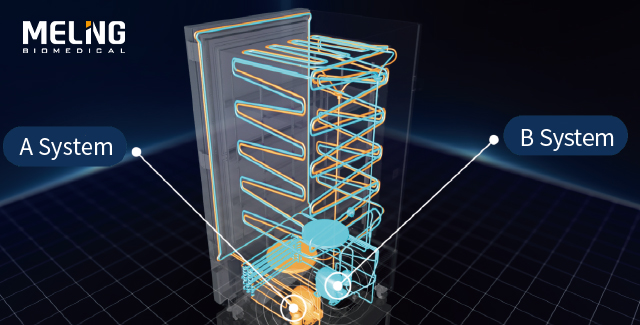

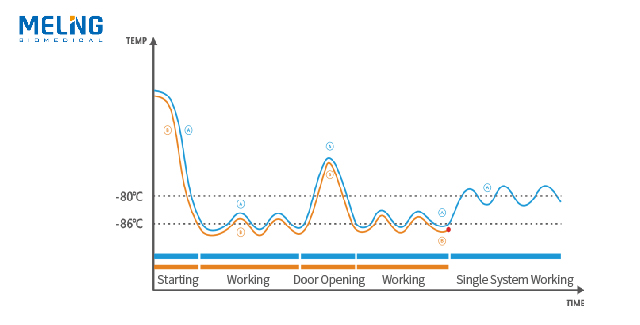

-86℃ Ultra Low Temperature Freezer:DW-HL1.8, DW-HL100HC

-40℃ Ultra Low Temperature Freezer:DW-FL90

The visitor showed interest in YC series since they need to store pharmacy materials. Also people ask about the refrigerator which has temperature range -40 ℃.

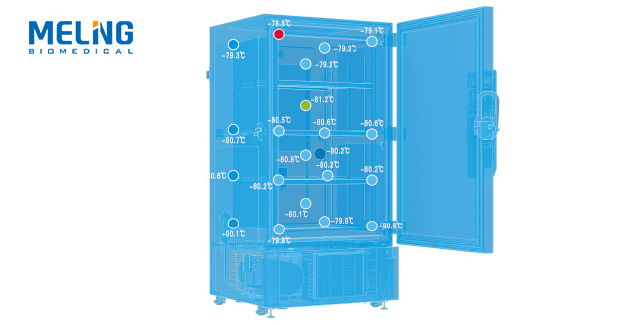

For Meling Biomedical’s pharmacy refrigerator series, it has air circulation with finned evaporator achieves fast cooling and ensures temperature uniformity in thecabinet.HC refrigerant with ultra low GWP minimize thermal radiation, meanwhile to reduce HVAC energy consumption.Equipped with various audible and visible alarms, including sensor failure alarm, low battery alarm, communication failure alarm, door ajar alarm and recorder not connected/not started alarm etc.

As of -40℃ Ultra Low Temperature Freezer-DW-FL90, it is pharmaceutical grade undercounter freezer and designed and manufactured for long term storage of various biological products, including Serum, plasma samples and etc.It owns high-efficiency refrigeration system and reliable security system like RS485 interface compliance to MODEBUS protocolable to transfer data with BMS console.Its keyboard lock function can prevent any adjustment of operating parameters without permission to ensure a double sample safety.

As a national new high-tech enterprise, we keep focusing on engaging in life science, family health and cold chain solutions. Meling Biomedical is aimed to create better products for users, give more benefits to customers.