Discover the Versatility and Reliability of Crepe Paper for Medical Applications

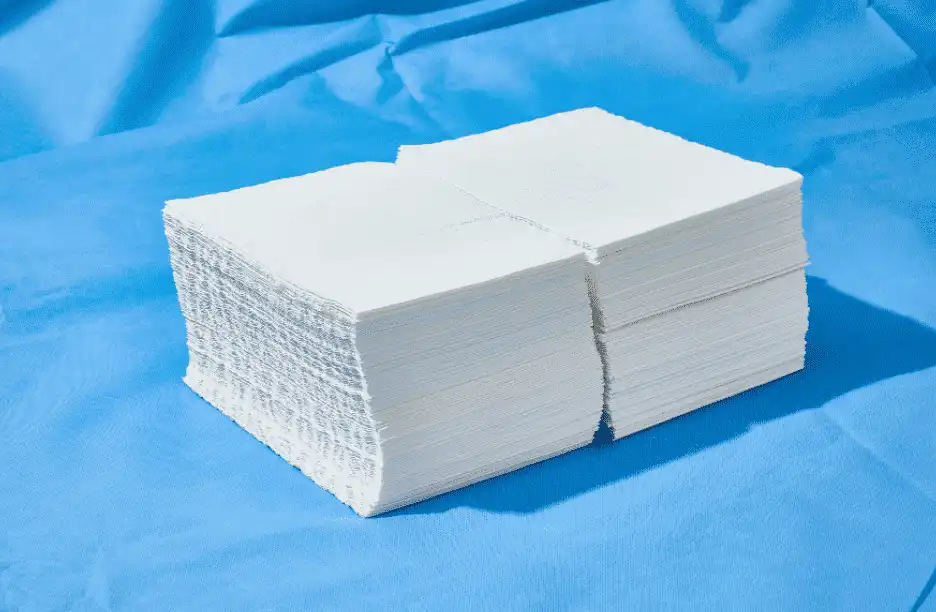

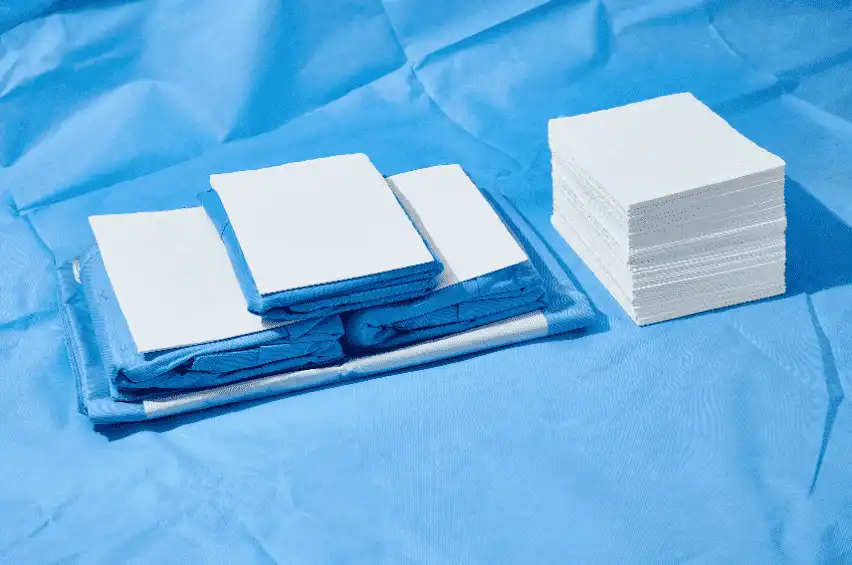

When it comes to medical packaging, selecting the right material is critical for maintaining product integrity and patient safety. Among the various options available, Crepe Paper stands out for its exceptional strength, flexibility, and superior barrier properties. It is widely used across healthcare facilities, providing a reliable solution for wrapping instruments and maintaining sterility throughout the surgical process.

One of the leading uses of Crepe Paper in healthcare is as a Medical Surgical Paper. Designed specifically for surgical procedures, this paper combines excellent breathability with the toughness required to endure the rigorous sterilization process. Its high adaptability allows it to conform easily to different shapes and sizes of medical tools, ensuring that every piece is securely wrapped and protected.、

Additionally, Crepe Paper serves as an outstanding Sterilization Wrapping Paper, offering both protection and performance under high-temperature and high-pressure conditions. Whether used in steam, EO (ethylene oxide), or plasma sterilization methods, this material ensures that the sterile barrier is preserved until the point of use. Hospitals and clinics worldwide trust this versatile solution to uphold their highest standards of hygiene and safety.

Choosing the right supplier for your Crepe Paper needs is just as important as the material itself. Telijie, a renowned name in the industry, offers top-grade Crepe Paper that consistently meets international standards. Beyond product quality, Telijie is committed to providing exceptional customer service, fast delivery, and professional technical support. Partnering with Telijie means not only securing the best materials but also enjoying a seamless, reliable experience tailored to your specific needs.